- English

- Japanese

- TEL

- 81-78-335-7573

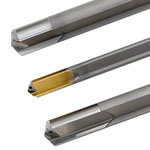

Double Crimp Gundrills

- Overview

-

The term double crimp is derived from the process of crimping the same tube used for the single flute gundrill, only crimping it twice, 180 degrees apart. Therefore, with the flute channels on this type of tool being somewhat shallower then the single flute, they limit the type of materials to be drilled by the chip size generated. The most common materials drilled are cast irons and cast aluminum. The double crimp has advantages. First, the coolant holes in the gundrill body are formed by the crimping action; therefore, minimizing the coolant turbulence at the head/body transition.

Second, the flutes being equally swaged 180 degrees apart allow for much greater rigidity. The double crimp gundrill can obtain feed rates twice that of its single flute partner. This is obtained by two cutting edges opposed to one another, and geometry angles ground to precise dimensions. With the combinations of geometry, clearances and backtaper, the chip load is reduced by 50% and higher penetration rates are obtained, making the double crimp gundrill the tool of choice for applications with free chipping materials.

Star SU double crimp gundrill can be used for high penetration in softer materials. Diameters available from .1875" - .5625". Lengths are available up to 72."

Gundrills

-

Single Flute Gundrills

The single flute gundrill, with its ability to machine very straight deep holes and hold excellent finishes, was originally developed for gun barrel manufacturing. Today, this drill is designed for deep hole drilling in virtually any material.

-

Solid Carbide Single Flute Gundrills

Solid carbide gundrills have a two-piece construction design. The tip and body are a single piece of carbide brazed into the driver/shank and the flute is ground down the length of the head and body. This rigid design has made its way into CNC machining centers and lathes, equipped with high pressure coolant delivery systems.

-

Two-Flute Two-Hole Gundrills

Often referred to as the “milled style,” the two-flute two-hole gundrill differs from the double crimp by the rigidity of its body. This rigid body allows for higher feed rates than traditional crimp body style drills.

-

Double Jet Gundrills

Star SU, with its years of experience in gundrilling developed a Star original patented Double Jet Gundrill. The most critical interface, in which the carbide is subjected to the most traumas, is during entry/exit of the part and during interruptions of the boring cycle.

-

Double Crimp Gundrills

The term double crimp is derived from the process of crimping the same tube used for the single flute gundrill, only crimping it twice, 180 degrees apart. Therefore, with the flute channels on this type of tool being somewhat shallower then the single flute, they limit the type of materials to be drilled by the chip size generated.

-

Bi-Tip Gundrills

Similar to the Two-Flute Two-Hole “milled style” product line engineered with a solid steel body, the Bi-Tip has an auger-like helix ground in the body.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.