- English

- Japanese

- TEL

- 81-78-335-7573

SEARCH

Coolant Filtration System

- Models

- Overview

-

Kenfilt is a worldwide active company in the field of development, construction and manufacturing of filtration equipment and central systems for any kind of coolants used in the different production processes in the Metalworking Industry.

Kenfilt have a strict quality control system in place to carry a complete supervision of all manufacturing stages from start to finish by applying the standard ISO 9001 as well as ISO 14001.

Their system can be used to manufacturers of precision machinery, car manufacturers, the cutting tool industry, the car accessory industry, together with other engineering industries.

Models

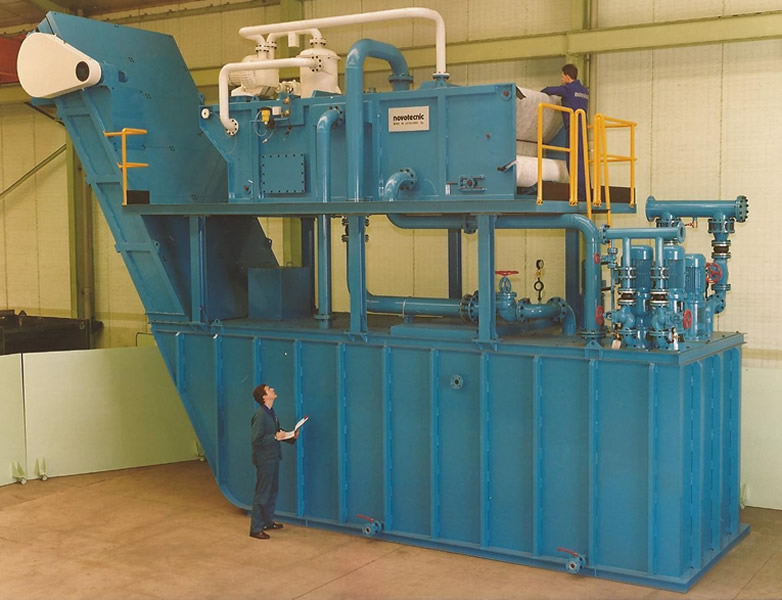

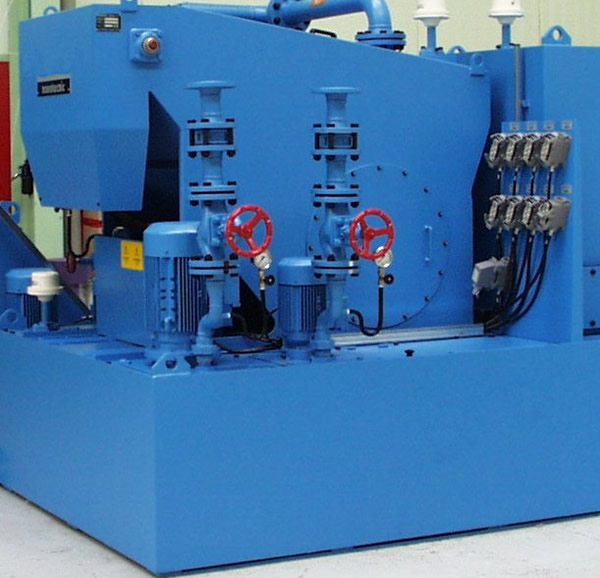

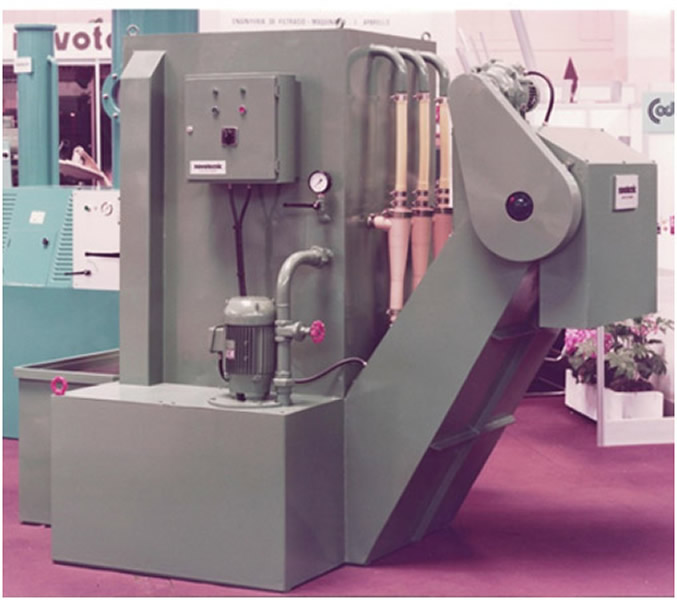

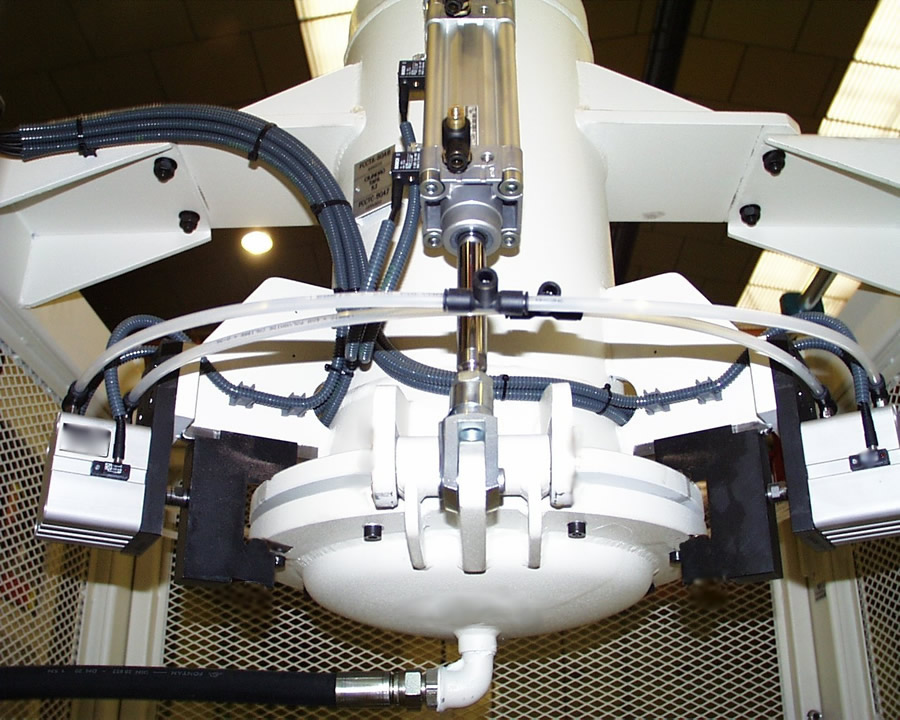

PRECOAT FILTERS

- Filtration

- Cutting oils, rolling oils, dielectric oils, hydraulic oils, kerosene, white spirit and other petroleum derivatives, synthetic solutions and micro emulsions.

- Processes

- Grinding, profiling, grinding grooves, burnishing drill,deep grinding of gears, cold rolled, EDM, and other washing.

- Nominal Filtration Quality

- 5 microns, depending on the type of filter aid used can be 2 microns.

- Flow

- 30 to 30,000 l / min and more.

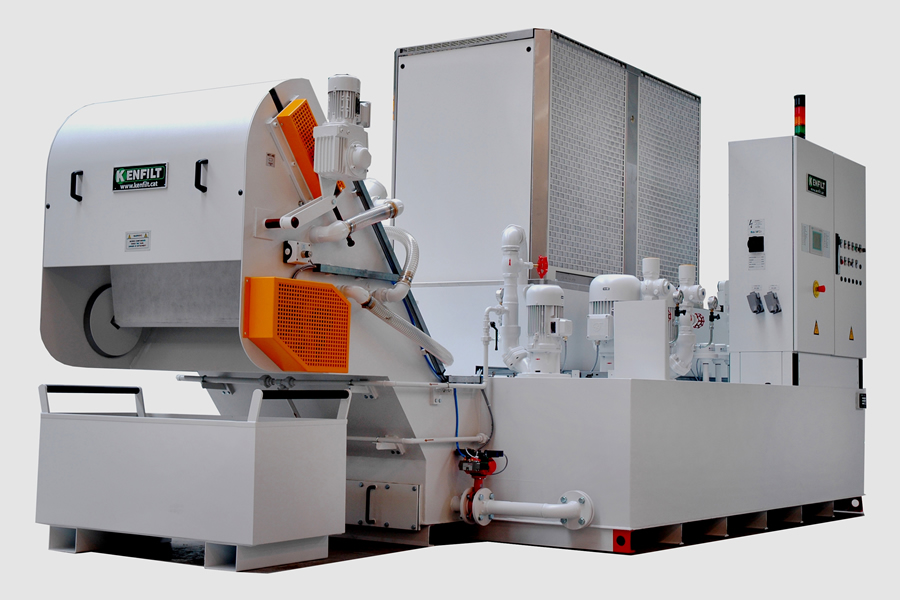

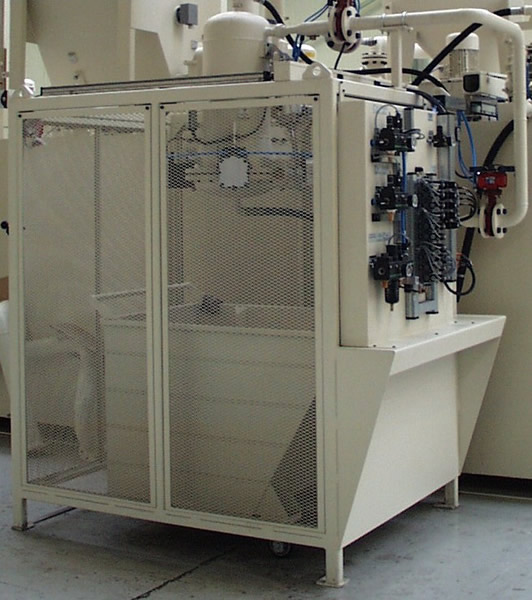

PNEUMATIC

- Filtration

- Emulsions and synthetic solutions (occasionally cutting oil).

- Processes

- General machining, grinding, hot rolled and cold, dry, etc.

that needs of a good nominal filtration quality. - Nominal Filtration Quality

- 10-80 microns, depending on the type of band filtering.

- Flow

- 1.000 to 30.000 l / min and more

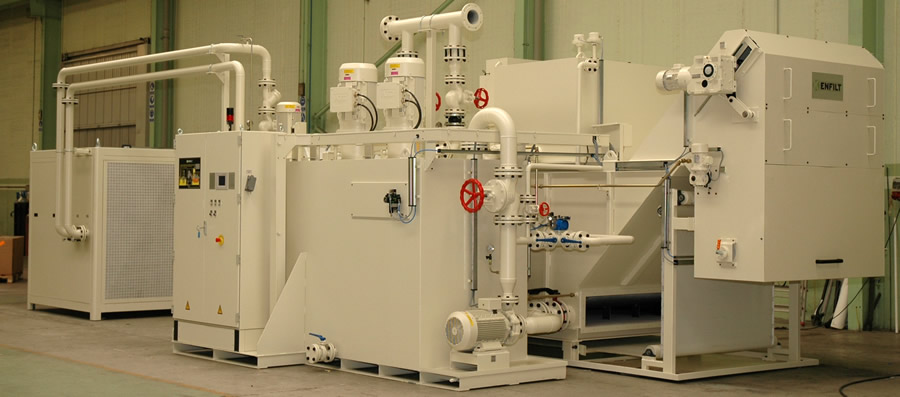

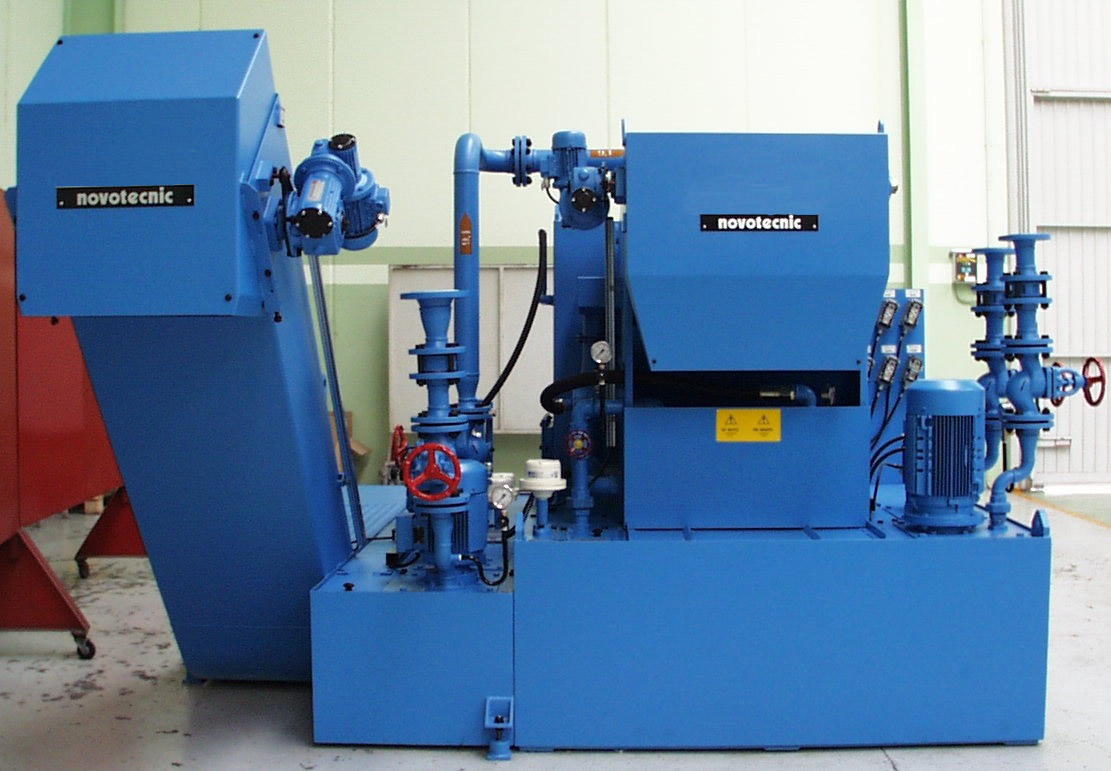

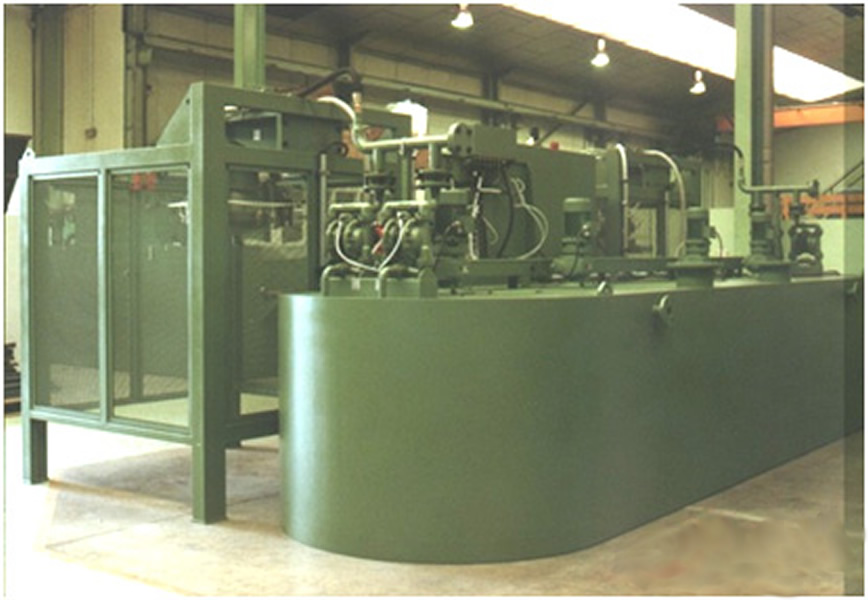

HYDRAULIC

- Filtration

- Emulsions and synthetic solutions (cutting oil for some cases).

- Processes

- General machining, grinding, hot-rolled, washing, etc., that meeds for a medium filtration quality.

- Nominal Filtration Quality

- Between 30 and 400 microns, depending on whether using a grid or a band filter type.

- Flow

- 1.000 to 30.000 l / min

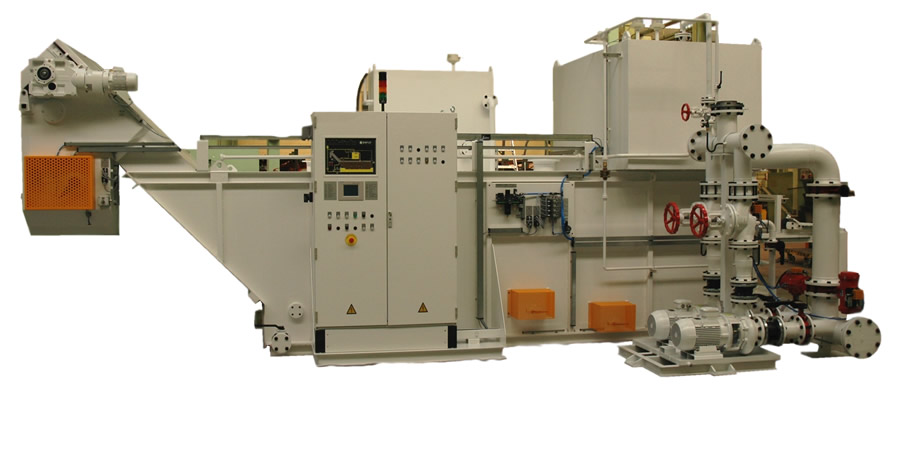

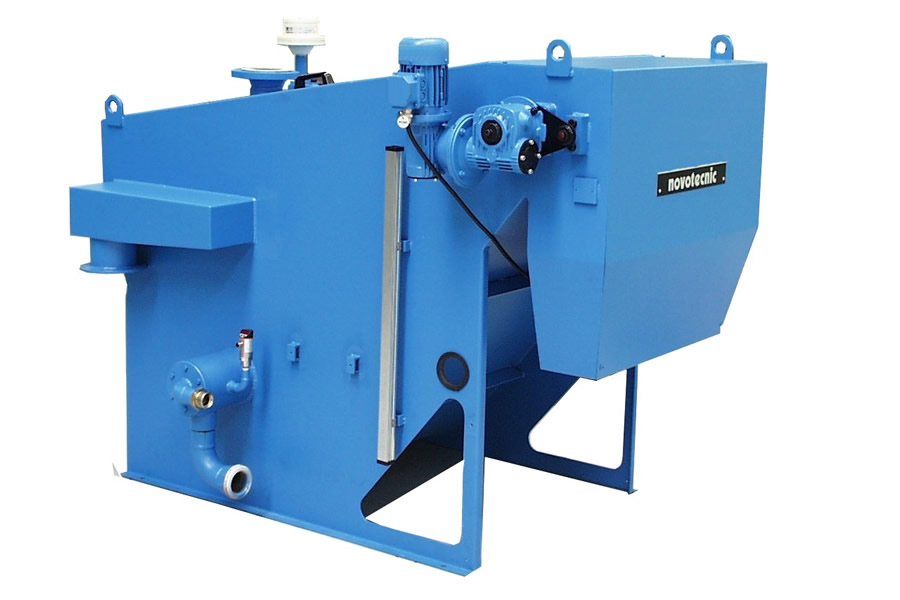

HYDROSTATIC

- Filtration

- Emulsions and synthetic solutions (occasionally cutting oil).

- Processes

- General machining, grinding, washing, etc., when the quality of filtration required is strict.

- Nominal Filtration Quality

- Between 15 and 100 microns, depending on the type of filter used.

- Flow

- 300 to 2.000 l / min.

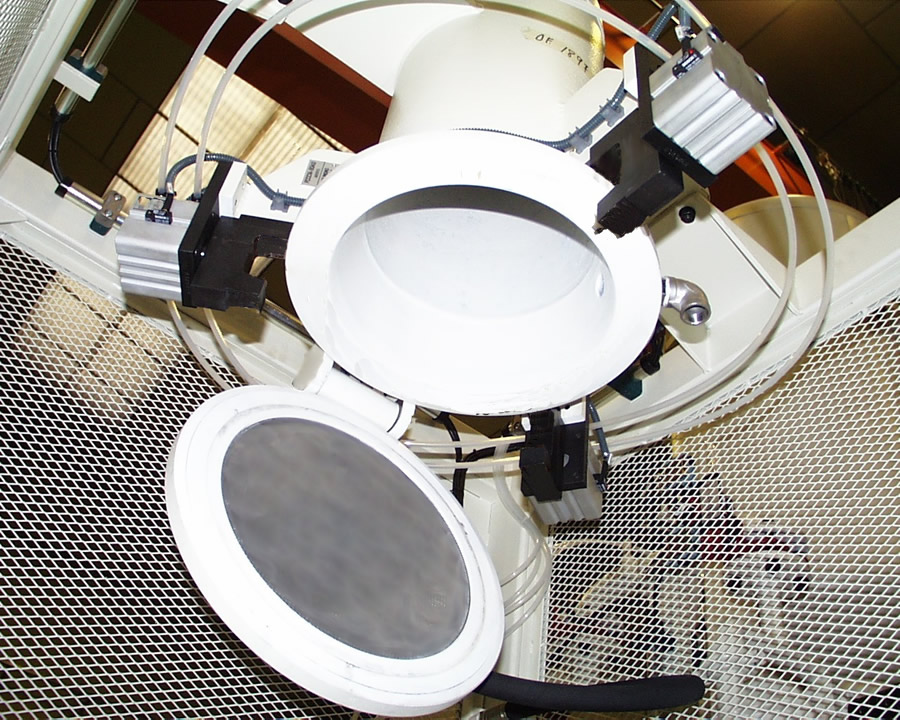

CANDLES W/O FILTER AID

- Filtration System with rigid candles WITHOUT CONSUMPTION OF FILTER MEDIA for

- Cutting oils, oil mills, micro emulsions, synthetic solutions, emulsions, kerosene, white spirit and other petroleum products.

- Processes

- Grinding profiles, grinding grooves, grinding gears, deep drilling, general machining, cold rolled and others.

- Nominal Filtration Quality

- 15 microns

- Flow

- 30 to 15,000 l / min and more

HYDRAULIC VACUUM DRUM

- Small Flow Filtration

- Emulsion and synthetic solutions.

- Processes

- General machining, grinding, etc., that do not need of a high quality filtration.

- Nominal Filtration Quality

- Between 30 and 100 microns, depending on the type of filter element used in the drum.

- Flow

- 100 to 400 l / min.

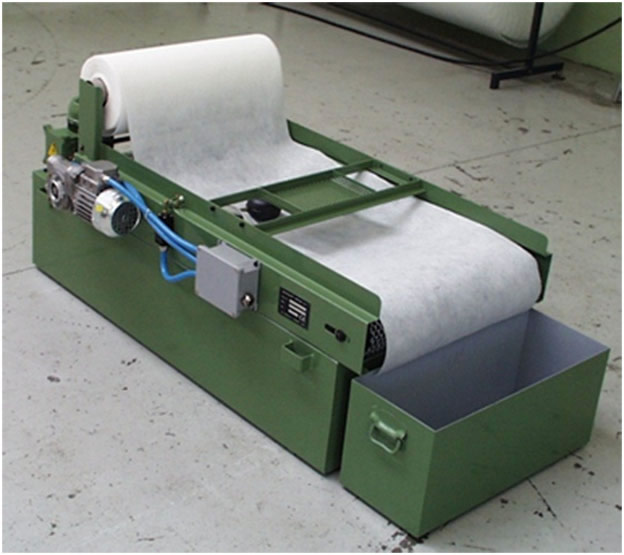

PAPER BAND

- Filtration

- Emulsions, synthetic solutions and washing solutions.

- Processes

- General machining that is required for filtration medium.

- Nominal Filtration Quality

- Between 50 and 400 microns, depending on the type of filter used hand.

- Flow

- 30 to 400 l / min.

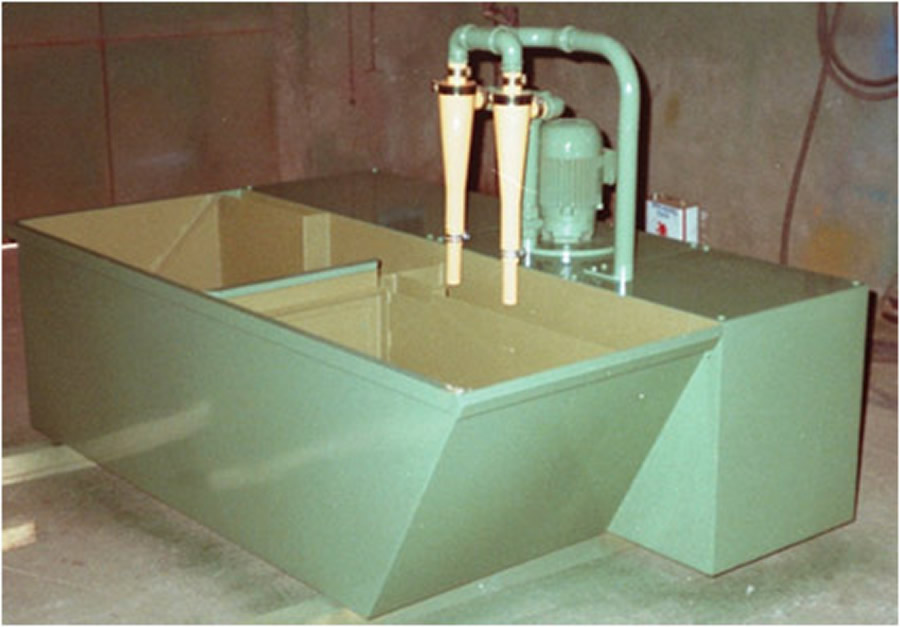

HYDROCYCLONE

- Cleaning of

- Emulsions and synthetic solutions.

- Processes

- Machining in general, grinding, hot rolling, etc...

were the quality of cleaning needed is not very strict. - Nominal separation quality

- 95 – 98% of particles bigger than 5 – 20 µm, with density equal or greater than steel.

- Flow

- 100 to 15.000 l/min and more.

LAMELLA DREDGE TANK

- Prefilter

- Water, synthetic solutions, emulsions, cutting oils, etc.

- Processes

- Hot rolling, cold rolling, ceramic and hard metal grinding, steel grinding, grinding in general.

- Separation eficiency

- 90%-95% , of solids in liquid.

- Flow

- 500 to 30.000 l/min and more.

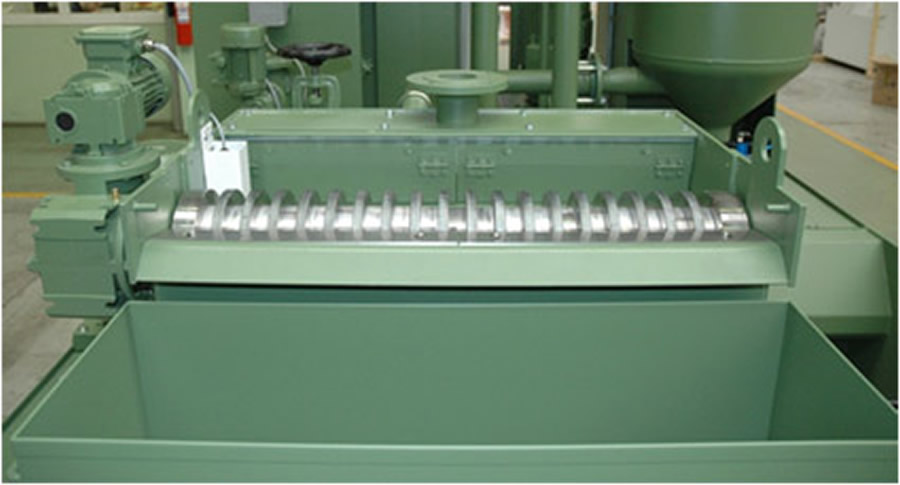

MAGNETIC SEPARATORS

- Depuration

- Emulsions, synthetic solutions and cuttng oils.

- Processes

- Normally used as a preseparation for more strict filtration systems.

- Nominal separation quality

- Case by case.

- Flow

- 20 to 1.500 l/min and more.

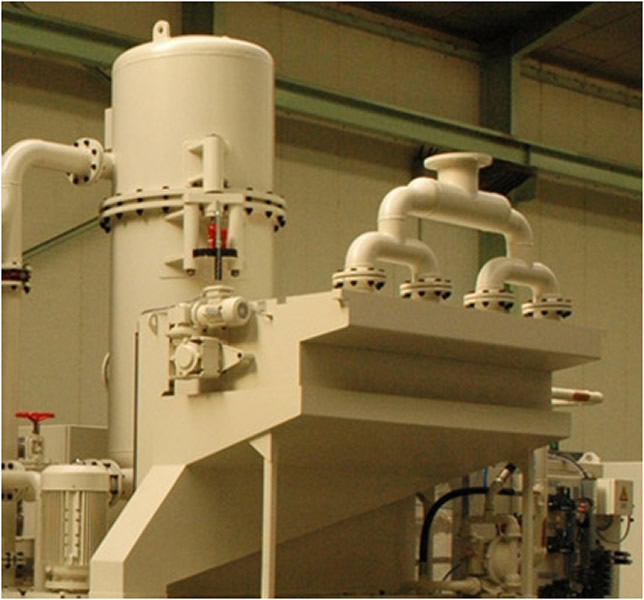

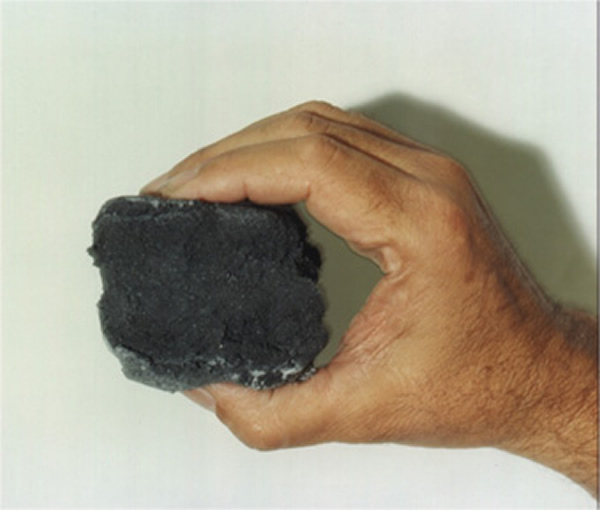

SLUDGE DRYING SYSTEM

Systems that dry with compressed air the sludge from a discharge of a precoat filter.The dried sludge contains aproximately 10-30% residual humidity which depends on:

- Type of liquid filtered

- Type of contaminant material

- Type of filter aid

The dried sludge might be disposed easily along with the industrial waste.

IMPORTANT NOTE

We have delivered CALL systems specially designed to be attatched to precoat systems and central systems from our competition, where an improvement of original drying capabilities were required.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.